How do microbes make the food industry better?

We don’t like our bread to go stale or our apples to rot. If they do, we curse our baker or the fruit vendor for not taking enough care during storage. As faulty storage can cause microbes to be active and spoil the food. Microbes are always unwelcome in our food world. Then, some foods are only complete with a microbe. Name a few examples:

- Bread needs yeast.

- Fermentation has an entire microflora.

- Cheese ripening is incomplete without a fungus.

So, microbes that behave themselves and are human-friendly become part of our food world.

The use of microbes in food has come a long way. Now, we talk about their application at the cellular level. To be precise, microbial enzymes are a recent trend in the food industry.

What are enzymes, and how do they work?

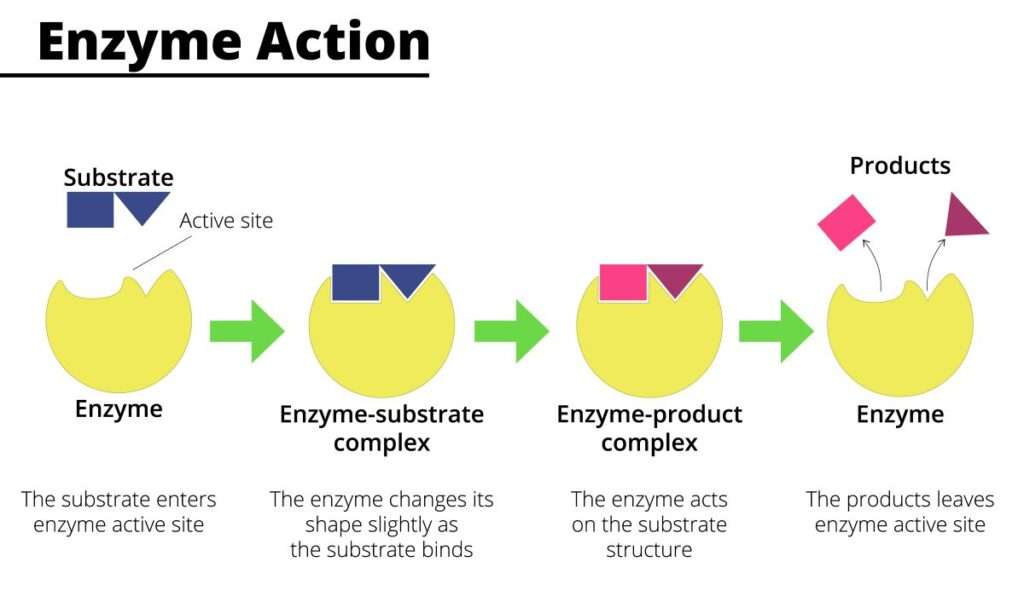

To be alive, a cell has to perform many chemical reactions. Creating energy from a food source to communicate with other cells is based on these reactions. But each of these reactions takes place at a plodding pace. They need a mediator to speed up the process. The enzymes are those mediators or catalysts.

Enzymes can be a protein or a nucleic acid. The protein one is discussed more regarding its application at an industrial level. Where it plays various roles in the making of processed food. Like improving the texture and flavor, speeding up the fermentation and ripening by many folds, and so on. But most importantly, it can do all the jobs of a chemical additive. It can potentially replace an emulsifier, a texturizer, and even a flavoring agent. The use of enzymes produces biodegradable waste. It also decreases energy consumption. Overall, the enzyme can turn the food industry into an eco-friendly zone.

What are microbial enzymes?

Every living cell can produce enzymes. With the help of advanced technology, the enzymes can be separated from the cells. Plants, animals, and microbes are familiar sources. But the one from the microbe is much more reliable. The factors that make microbial enzymes the first choice are:

- The production is easy and economical.

- It is not seasonal, like plants.

- Microbes can grow on a large scale and show rapid growth. It can lead to high yields.

- It is easy to modify microbial enzymes genetically.

How are enzymes made from microbes?

Enzymes are obtained from microbes through fermentation. There are two types of processes:

- Submerged fermentation: In this method, the microbes are grown in a liquid medium with high oxygen levels.

- Solid State fermentation: The microbes are grown on agricultural residues. It is less expensive.

The microbes release the enzymes into the medium, either solid or liquid. It is natural to break down complex foods into simpler ones. And feed on it. These released enzymes can easily be extracted from the medium. Even a colony of microbes is a good source. However, it has to undergo an expensive precipitation and purification process.

Use of enzymes from microbes in the Dairy Industry

Enzymes are the heart of the Dairy Industry. From curdling to the ripening of cheese, all are enzyme-based processes. The use of rennet in curdling milk is an age-old method. The rennet is obtained from the fourth stomach of the suckling calf. With time, animal rennet is getting less available because of its stringent standards. In such cases, microbial rennet from fungi, Rhizomucor miehei, can be an alternative. Rennet is made of two enzymes, chymosin, and pepsin. The microbial rennet acts like a chymosin. But its activity is less than that of animal rennet.

Cheese ripening is a process to improve the texture and flavor of the cheese. It is the result of the breakdown of fats and proteins. So, it requires lipases and proteases to carry out the reaction. Mostly, it is taken care of by naturally growing fungi and bacteria. However, adding the enzymes from outside shortens the process. The studies found that lipase, when added to the milk before rennet, speeds up the flavor production in a short ripening period.

Next on the list is the removal of allergens from the milk. Lactose is the one that creates a lot of trouble. Removal or breakdown of lactose not only makes the milk edible but also helps in many other ways;

- Lactose forms crystals in ice cream. So, removal helps reduce the lactose crystals.

- It reduces the time of fermentation.

- It causes a depression in the freezing point. So, milk with broken-down lactose makes better ice cream.

- In flavored milk, it improves the flavor and sweetness.

The enzyme lactase, or β-galactosidase, breaks down lactose into simpler forms. The sources are the yeasts K. fragilis, K. lactis and the fungi A. niger and A. oryzae.

The use of microbial enzymes in Bakery

The staling of bread is both a boon and a curse in the bakery industry. Stale bread loses its texture, making it hard and chewy. It loses its freshness, which makes it less palatable. The probable reason is the breakdown of starch gels and the loss of moisture from starch granules. But stale bread is also good for many dishes. Yet a baker looks for every possible answer to keep the bread fresh until it is sold. There are a number of enzymes that can solve a baker’s problem.

- α-amylase and xylanase have anti-staling properties. Amylopectin in starches is the one that can hold the starch gel together and prevent it from breaking down. Once broken down, the starch granules re-crystallize and lose water, making the bread dry. Both amylases control amylopectin breakdown. It helps to maintain the network and the bread’s elasticity and moisture.

- Enzymes like oxidase, lipase, and xylanase improve the strength of gluten.

- Even the enzyme phospholipase makes emulsifying lipids. These are extracted from A. niger, R. oryzae, and C. cylindracea.

- Thus, it improves shelf life, controls no-enzymatic browning, increases loaf volume, and improves crumb structure.

The use of microbial enzymes in the Beverage Industry

The microbial enzymes are useful for both fruit juice and alcoholic beverages. To boost the fermentation, the alcoholic beverage needs external enzymes. But why is an enzyme needed for fruit juice? Let’s find out.

- The enzymes like pectinase, xylanase, and amylase help release the juice from the pulp.

- Clarification is an important step in juice making. Solid particles like pectin and carbohydrates make the juice turbid. The process removes such particles and makes the juice clear. It reduces sulfur’s odor and improves the color as well. Pectinase and amylase are good at clarifying juices.

We can’t leave out the beer.

- In the case of beer, lactase takes care of the clarification part.

- The acidic fungal proteases improve the brewing even at low pH.

- Glucoamylase also helps in beer production.

Use of enzymes from microbes in the flavor industry

The use of flavors in food is one of the oldest practices in the food industry. Adding a few drops of these flavors can make food fresh. It helps to revive the lost aroma due to processing. Almost all the flavors used fall under the category of esters. These are mostly extracted from their natural source chemically. But these days, buyers are looking for natural products. So, most of the companies are cutting down on the use of chemicals in their products. They are choosing enzymes as an alternative.

Many enzymes are used in the industry, but lipase is the most studied and widely used. Lipase can produce flavor esters when put into organic solvents, like

- Isoamyl acetate has a flavor similar to banana and pear.

- Isoamyl butyrate is used as a fruit flavor. It is similar to the flavors of apricot, melon, and mango. It is also found in wine, eucalyptus oil, and coconut oil.

- Geranyl acetate has a floral or fruity rose aroma.

- Citronellyl acetate has a rose note with a fruity undertone.

To date, thousands of microbial enzymes have been studied and researched. But when it comes to the application, it still needs to be well explored. The industry is struggling with the idea of whether or not to be part of the enzymatic world. With all their benefits, one cannot deny that enzymes are the future of the food industry.